Optimizing a Car Bumper: Lighter and Safer with FEA

Project Overview

This project focused on reducing the weight of a sedan bumper without compromising safety, using Finite Element Analysis (FEA) in ANSYS. The aim was to balance fuel efficiency with crashworthiness by comparing a baseline bumper design against an optimized version featuring three front-face holes.

Project Details and Methods

This project focused on optimizing the weight of a car bumper without compromising passenger safety. Using Finite Element Analysis (FEA) in ANSYS, two bumper designs were modeled and compared: a standard curved impact bar and an optimized version with strategically placed holes. The optimized design was approximately 7.5% lighter while also absorbing more crash energy, proving that efficiency and safety can be achieved together.

What set this project apart was not just the numerical results but the engineering rigor behind them. A complex dynamic crash was simplified into a static FEA problem, Gaussian load distributions were applied, multiple mesh refinements were tested for convergence, and results were validated against Euler–Bernoulli beam theory. Beyond simulation, the analysis identified limitations introduced by simplifications and clearly communicated why physical crash testing would still be required for final validation.

FEA Results

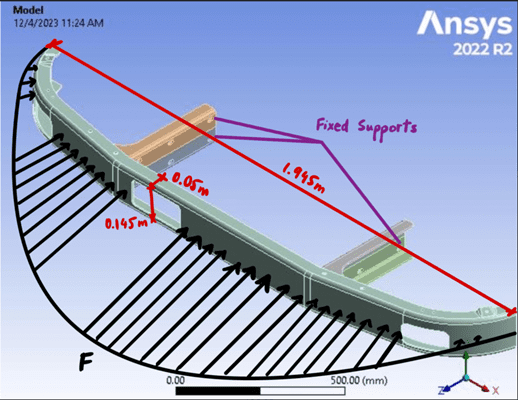

- Schematic of the static problem simulated in ANSYS. The load was applied as a gaussian load across the front of the bumper, with the maximum load applied at the centre with a magnitude of 206.1 kN. The end to end length of the bumper is 1945 mm and the height is 145 mm. The thickness of the sheet metal is 5 mm. The holes in the bumper suports were used as fixed supports.

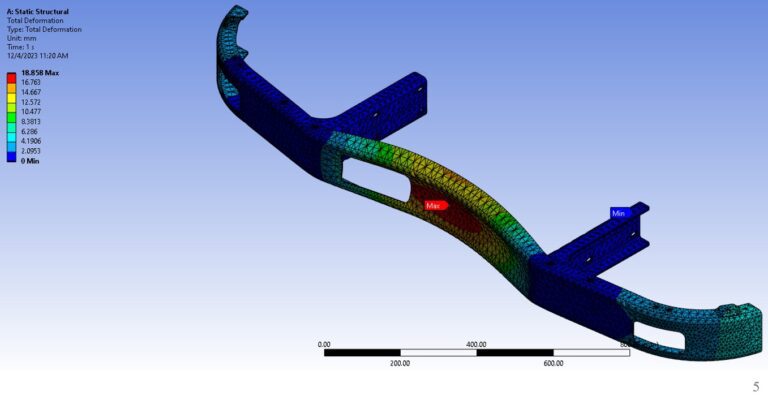

Total deformation contour of the converged result for deformation of the bumper with holes (Design 1). The maximum deformation of 18.858 mm occurs at the centre of the bumper.

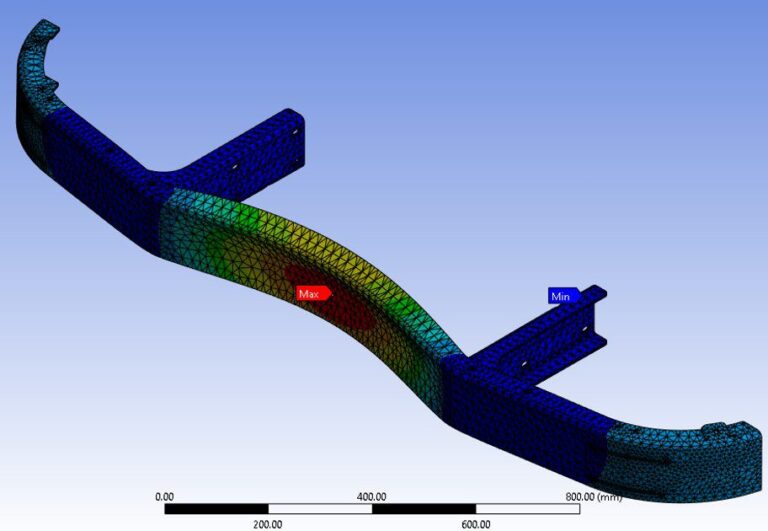

Total deformation contour of the converged result for deformation of the bumper without holes (Design 2). The maximum deformation of 16.231 mm occurs at the centre.

Learnings

The outcome demonstrated not just technical ability in simulation, but also an optimization mindset, systems-level thinking, and the ability to balance performance trade-offs, skills that are essential in designing products that are both innovative and uncompromising in quality.

Skills Developed:

Proficiency with ANSYS Workbench and FEA simulation workflows

Experience with mesh refinement, convergence testing, and load modeling

Ability to validate numerical results against analytical theory

Practice in design optimization and trade-off decision-making

Development of systems-level thinking linking part-level changes to overall performance